Stark Aerospace – state-of-the-art Manufacturing Facility

Stark Aerospace offers build-to-print, build-to-spec & production services for Aerostructures and Composites from component level to fully integrated assemblies and structures. Stark’s capabilities include welding, machining parts, special paint process, electrical wire harnesses, final assembly, and integration for missile programs and manufacturing, repair & calibration of electro-optical payloads and other electronics.

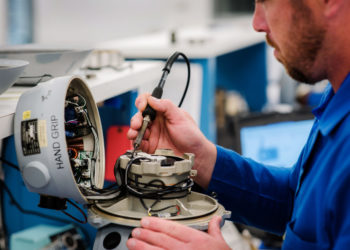

AEROSTRUCTURES

- Boeing 787 Floor Beam Assemblies

- Boeing 787 Door Surround Assemblies

- Gulfstream G280 Fairings – Prepreg Layup

- Carbon Fiber & Fiber Glass Laminate and Honeycomb Structures

- Hunter Fuselage, Wing Repair – Wet Layup Oven Cure

- Carbon Fiber & Fiber Glass Laminate and Honeycomb Structures

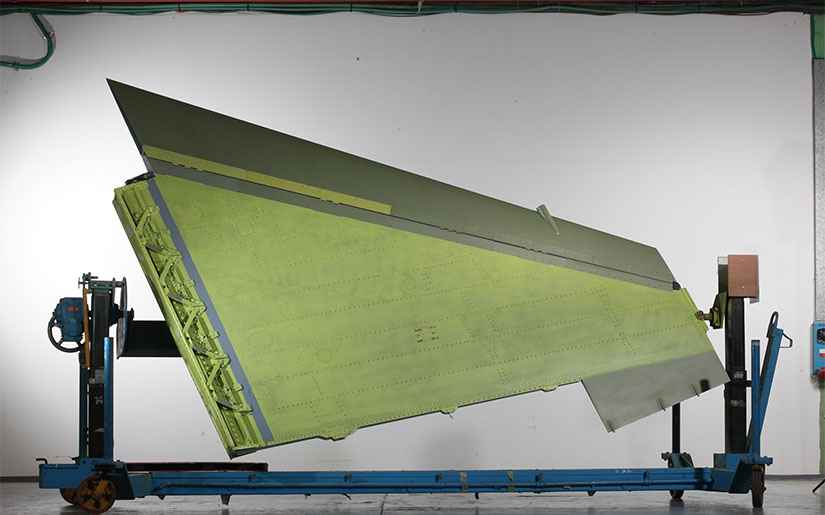

COMPOSITES

Manufacturing

- Carbon Fiber & Fiber Glass Laminate and Honeycomb Structures

- 2,500 SF Certified Class 100,000 (ISO 8) Clean Room

- Wi-Fi temp & humidity control

- VIRTEK Laser Projection

- Gerber Ply Cutter

- Additional 29,000 SF for cured composite assemblies

Autoclave

- Diameter: 12 FT /Length: 30 FT

- Max Temp/Pressure: 500F/ 135psi

Paint booth

- 15,000 cubic feet

- Climate controlled

- Up to 150F cure cycles

- Post-Cure oven on-site 10 FT x 60 FT

- MIL-STD Primer and Topcoats

- Fuel Tank and Fay Surface Sealant

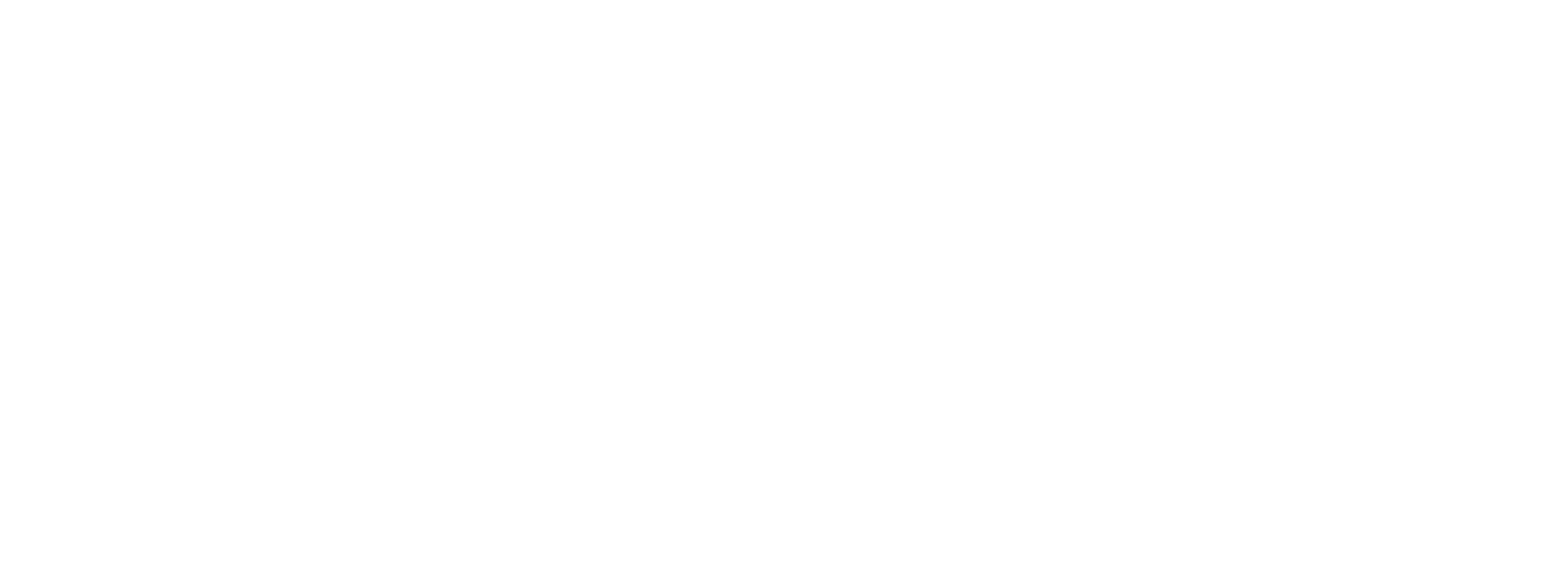

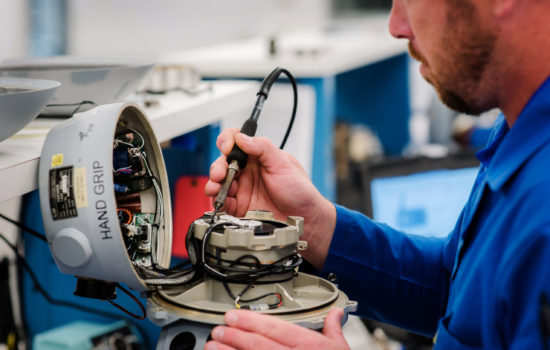

ELECTRO OPTICS

Assembly and Repair of Gyroscopic Units, EO/IR Sensors,

& Electronic Boxes

- 5,600 SF Certified Class 100,000 Clean Room (ISO 8)

- Temp & Humidity Control

- ESS Testing

- IPC J-STD-001 Soldering Certification

- Ideal Aerosmith Rate Table for Gyroscopic Testing

- Line of Sight Calibration

- IPC-A-610 Certification

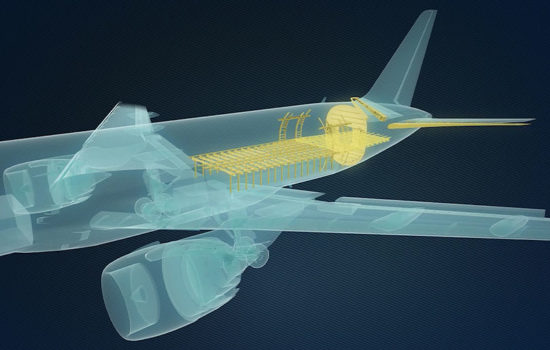

MISSILE PROGRAMS

Canister Manufacturing

- Tig Welding

- Sheet Metal Assemblies

- Wire Harness Integration and Testing

- Nitrogen Purity Testing

- Pressure Testing for Gas Lines

- Special Processes

- 1,870 Cubic Ft. Sandblasting Booth

- Thermal Zinc Sprayer for Anti-corrosion Coating

- Laser Shearography for Non-Destructive Testing